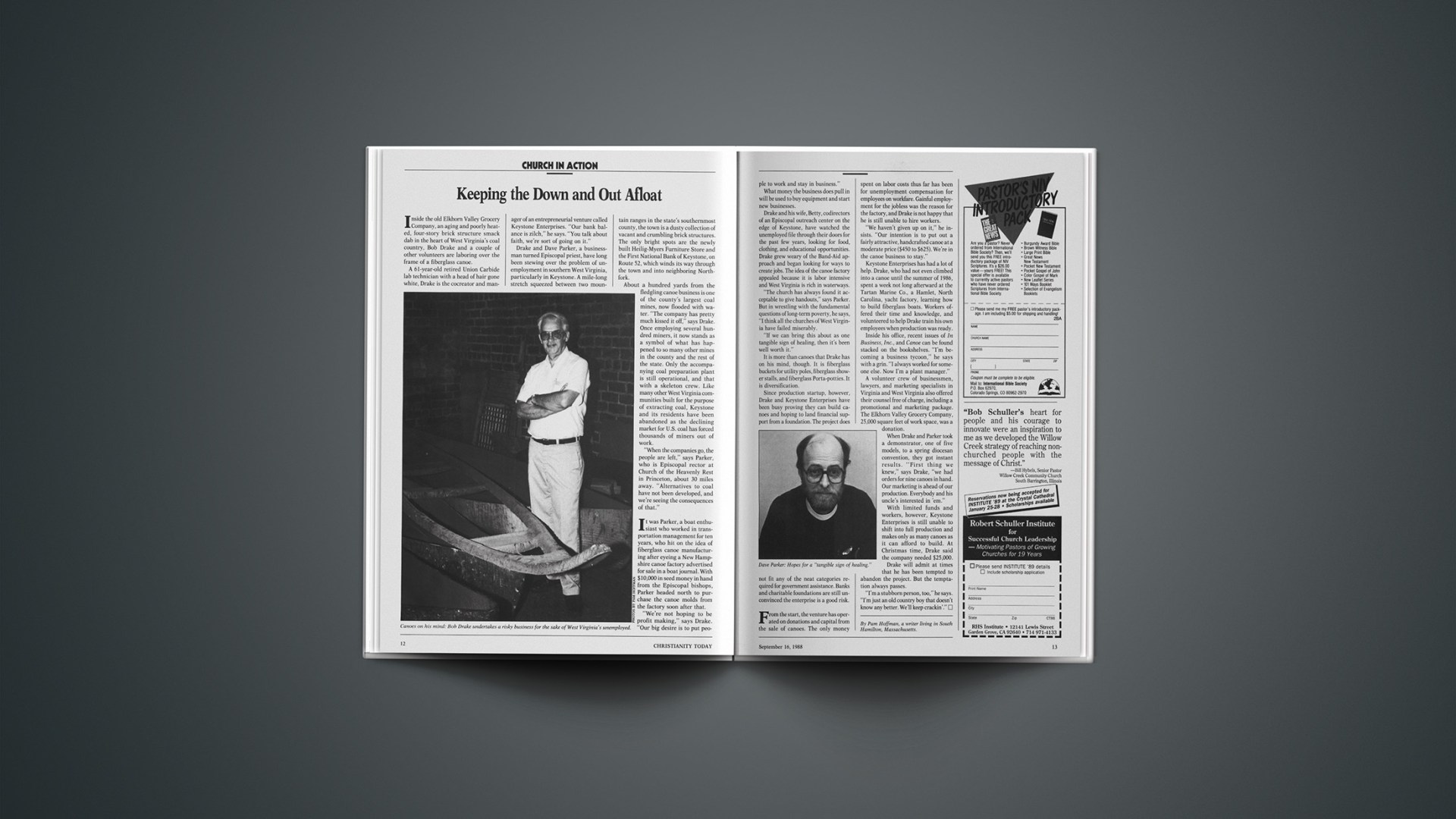

Inside the old Elkhom Valley Grocery Company, an aging and poorly heated, four-story brick structure smack dab in the heart of West Virginia’s coal country, Bob Drake and a couple of other volunteers are laboring over the frame of a fiberglass canoe.

A 61-year-old retired Union Carbide lab technician with a head of hair gone white, Drake is the cocreator and manager of an entrepreneurial venture called Keystone Enterprises. “Our bank balance is zilch,” he says. “You talk about faith, we’re sort of going on it.”

Drake and Dave Parker, a businessman turned Episcopal priest, have long been stewing over the problem of unemployment in southern West Virginia, particularly in Keystone. A mile-long stretch squeezed between two mountain ranges in the state’s southernmost county, the town is a dusty collection of vacant and crumbling brick structures. The only bright spots are the newly built Heilig-Myers Furniture Store and the First National Bank of Keystone, on Route 52, which winds its way through the town and into neighboring Northfork.

About a hundred yards from the fledgling canoe business is one of the county’s largest coal mines, now flooded with water. “The company has pretty much kissed it off,” says Drake. Once employing several hundred miners, it now stands as a symbol of what has happened to so many other mines in the county and the rest of the state. Only the accompanying coal preparation plant is still operational, and that with a skeleton crew. Like many other West Virginia communities built for the purpose of extracting coal, Keystone and its residents have been abandoned as the declining market for U.S. coal has forced thousands of miners out of work.

“When the companies go, the people are left,” says Parker, who is Episcopal rector at Church of the Heavenly Rest in Princeton, about 30 miles away. “Alternatives to coal have not been developed, and we’re seeing the consequences of that.”

It was Parker, a boat enthusiast who worked in transportation management for ten years, who hit on the idea of fiberglass canoe manufacturing after eyeing a New Hampshire canoe factory advertised for sale in a boat journal. With $10,000 in seed money in hand from the Episcopal bishops, Parker headed north to purchase the canoe molds from the factory soon after that.

“We’re not hoping to be profit making,” says Drake. “Our big desire is to put people to work and stay in business.”

What money the business does pull in will be used to buy equipment and start new businesses.

Drake and his wife, Betty, codirectors of an Episcopal outreach center on the edge of Keystone, have watched the unemployed file through their doors for the past few years, looking for food, clothing, and educational opportunities. Drake grew weary of the Band-Aid approach and began looking for ways to create jobs. The idea of the canoe factory appealed because it is labor intensive and West Virginia is rich in waterways.

“The church has always found it acceptable to give handouts,” says Parker. But in wrestling with the fundamental questions of long-term poverty, he says, “I think all the churches of West Virginia have failed miserably.

“If we can bring this about as one tangible sign of healing, then it’s been well worth it.”

It is more than canoes that Drake has on his mind, though. It is fiberglass buckets for utility poles, fiberglass shower stalls, and fiberglass Porta-potties. It is diversification.

Since production startup, however, Drake and Keystone Enterprises have been busy proving they can build canoes and hoping to land financial support from a foundation. The project does not fit any of the neat categories required for government assistance. Banks and charitable foundations are still unconvinced the enterprise is a good risk.

From the start, the venture has operated on donations and capital from the sale of canoes. The only money spent on labor costs thus far has been for unemployment compensation for employees on workfare. Gainful employment for the jobless was the reason for the factory, and Drake is not happy that he is still unable to hire workers.

“We haven’t given up on it,” he insists. “Our intention is to put out a fairly attractive, handcrafted canoe at a moderate price ($450 to $625). We’re in the canoe business to stay.”

Keystone Enterprises has had a lot of help. Drake, who had not even climbed into a canoe until the summer of 1986, spent a week not long afterward at the Tartan Marine Co., a Hamlet, North Carolina, yacht factory, learning how to build fiberglass boats. Workers offered their time and knowledge, and volunteered to help Drake train his own employees when production was ready.

Inside his office, recent issues of In Business, Inc., and Canoe can be found stacked on the bookshelves. “I’m becoming a business tycoon,” he says with a grin. “I always worked for someone else. Now I’m a plant manager.”

A volunteer crew of businessmen, lawyers, and marketing specialists in Virginia and West Virginia also offered their counsel free of charge, including a promotional and marketing package. The Elkhom Valley Grocery Company, 25,000 square feet of work space, was a donation.

When Drake and Parker took a demonstrator, one of five models, to a spring diocesan convention, they got instant results. “First thing we knew,” says Drake, “we had orders for nine canoes in hand. Our marketing is ahead of our production. Everybody and his uncle’s interested in ‘em.”

With limited funds and workers, however, Keystone Enterprises is still unable to shift into full production and makes only as many canoes as it can afford to build. At Christmas time, Drake said the company needed $25,000.

Drake will admit at times that he has been tempted to abandon the project. But the temptation always passes.

“I’m a stubborn person, too,” he says. “I’m just an old country boy that doesn’t know any better. We’ll keep crackin’ ”

By Pam Hoffman, a writer living in South Hamilton, Massachusetts.